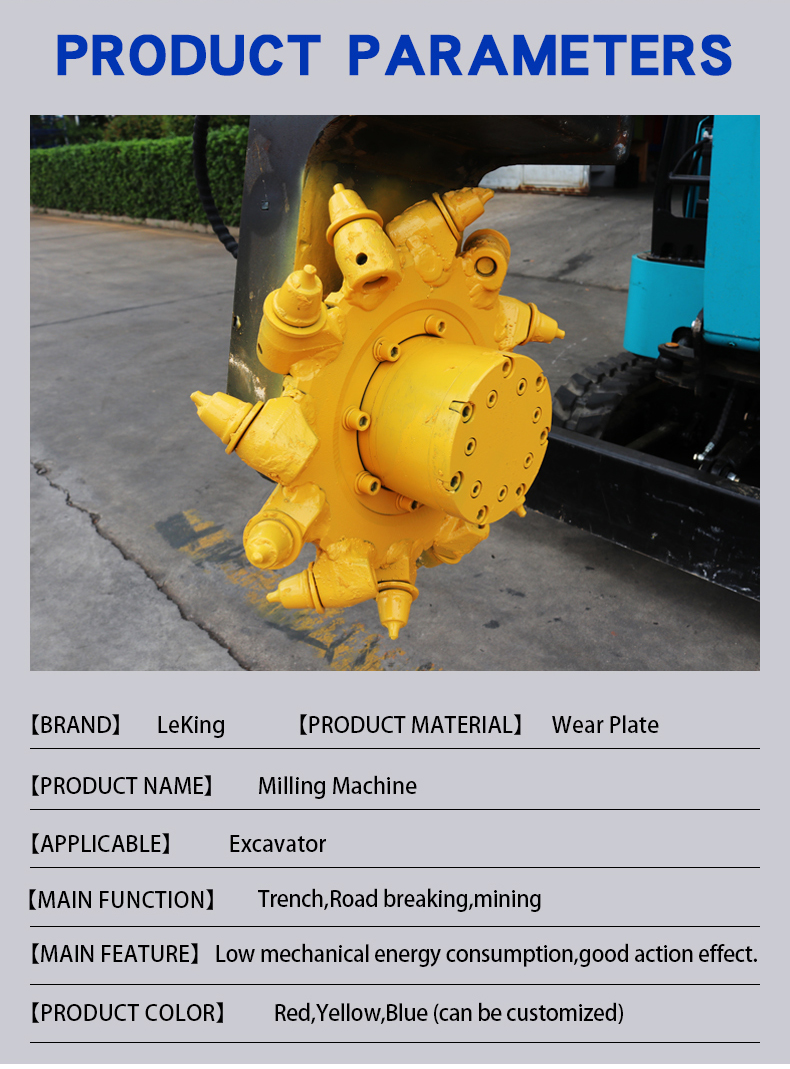

Excavator Milling Head / Excavator Milling Machine

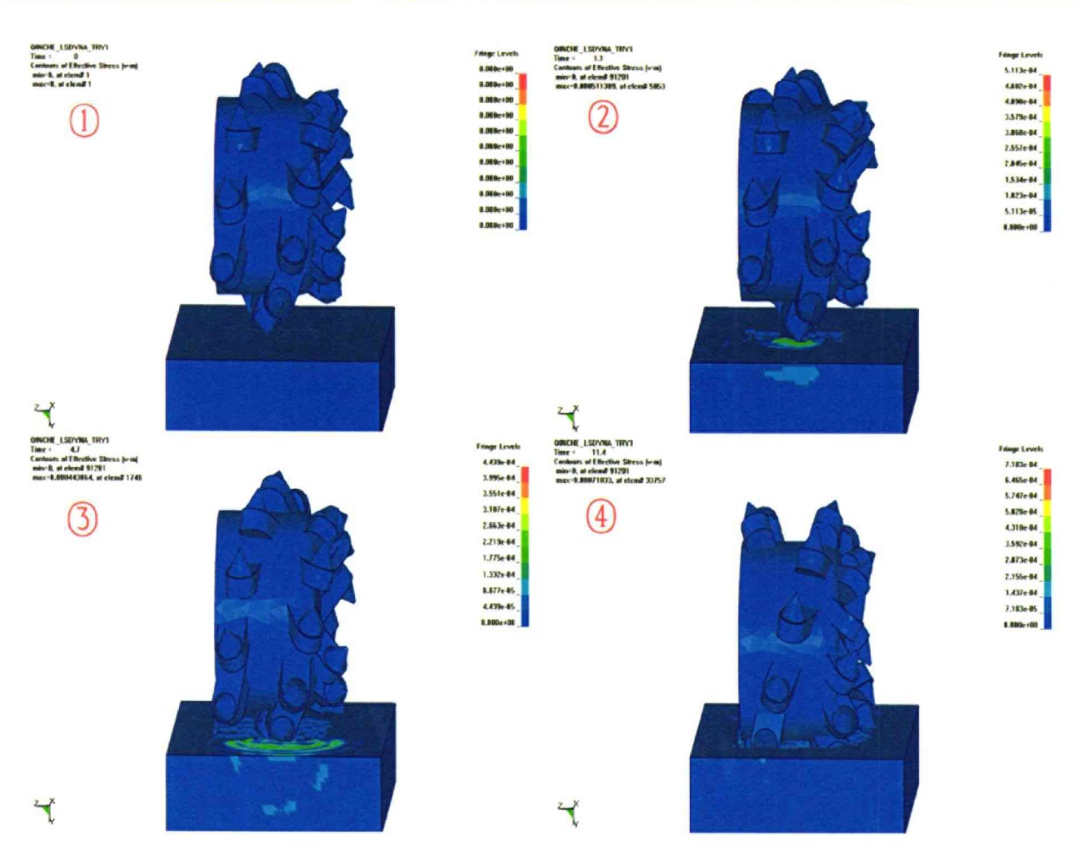

Excavator Milling Machine, also known as the milling and excavating head, is an auxiliary tool for the excavation and trimming of mines, tunnels, diversion culverts, subways, etc. , breaker, hydraulic shear and other general equipment, used in tunnel excavation and contour correction, low disturbance to the stratum during the excavation process, small noise, high excavation safety, especially suitable for blasting construction areas.

The milling and excavating machine is specialized in various purposes such as excavation, grooving, brushing, trimming, etc., and cooperates with the excavator to realize milling, excavation, loading, transportation, etc. - a machine with multiple purposes, suitable for use in various mines, with complete procedures, It is especially suitable for the excavation of small tunnels in coal mines, with fast excavation speed, safety, low energy consumption, low consumption, and one-time forming.

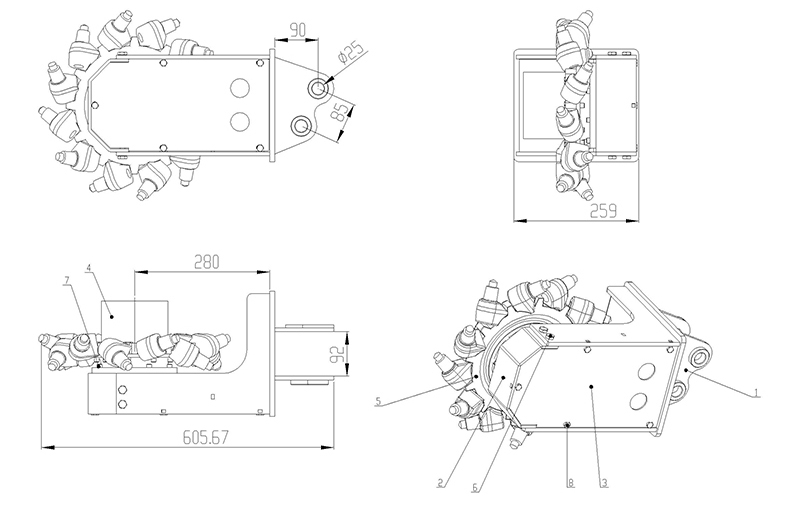

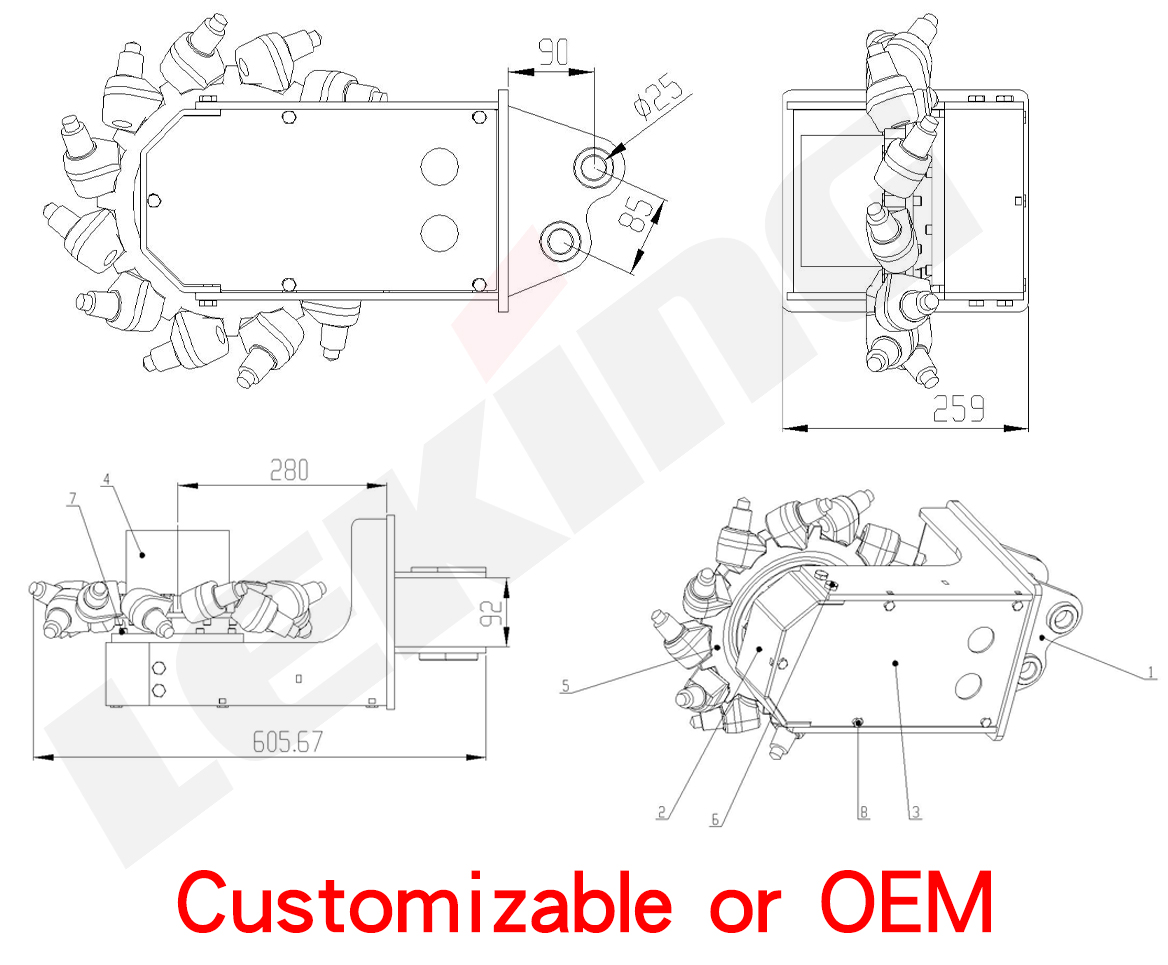

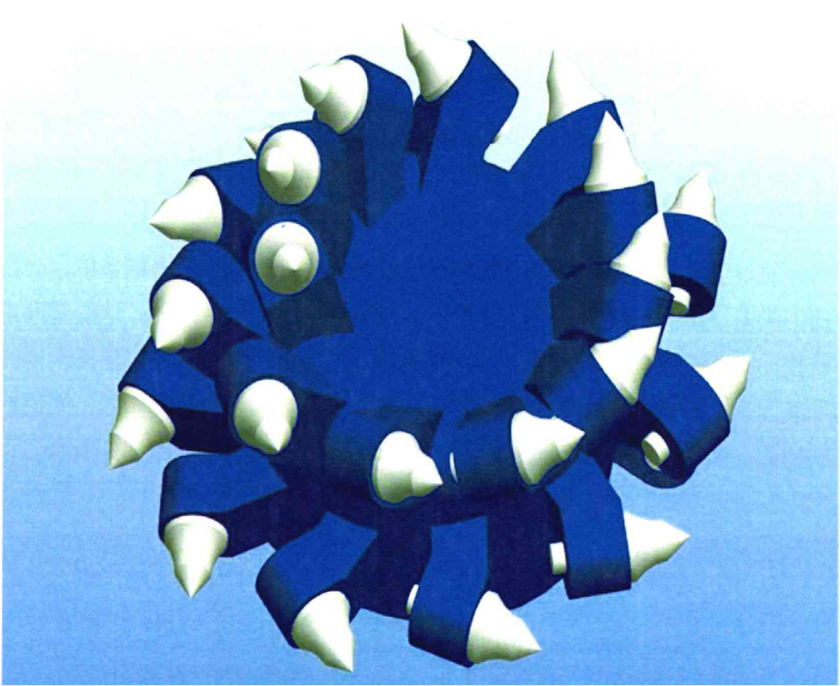

There are two basic types of milling machines: horizontal milling machines and vertical milling machines; their super-strong housing and gearbox design provide long service life. The all-round working angle can realize 360-degree rotation by itself, which is convenient for maintenance, no need to apply butter and nitrogen, and there are no special requirements for the maintenance of the excavator.

In addition, the milling machine is significantly effective in the demolition of buildings in milling and excavating foundations, concrete slabs, and concrete walls with few heavy steel reinforcements. It can realize the dual functions of hydraulic breaker and hydraulic pliers, because it can mill the steel bars in the building at the same time; the particle size of the milled material is small and can be directly used as backfill.

Features and uses of milling heads

◆Main hydraulic safety valve

◆Heavy duty seals and bearings

◆Simple oil circuit design

◆Low-speed high-torque motor direct drive

◆Protect the environment

◆Low noise and low vibration

◆High torque output.

◆No oil drain pipe

◆Precise shaping of trenches, tunnels and surfaces

◆Little harm to surrounding buildings

◆Suitable for a wide range of applications

◆The working area can be directly backfilled with milling and excavating materials

◆Mining

◆Tunnel engineering

◆Water conservancy and hydropower

◆River repair

◆Trench excavation

◆ Obstacle removal

◆Slope trimming

◆Permafrost construction

◆Sinking