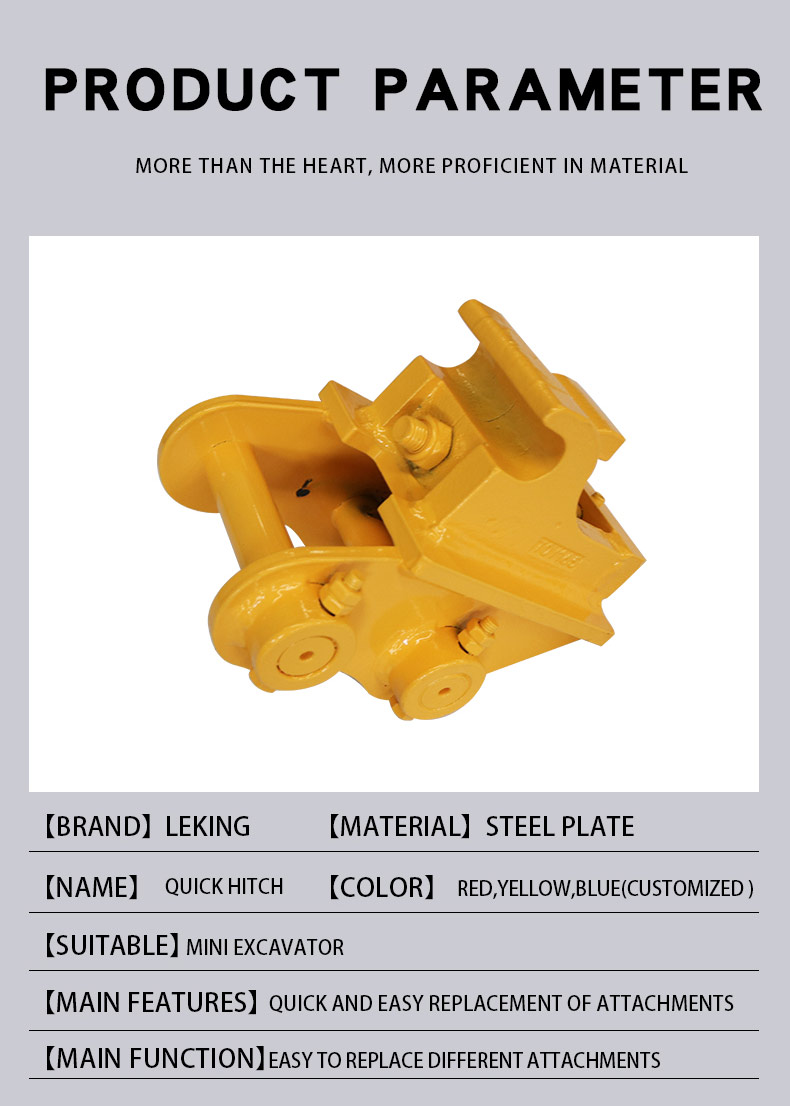

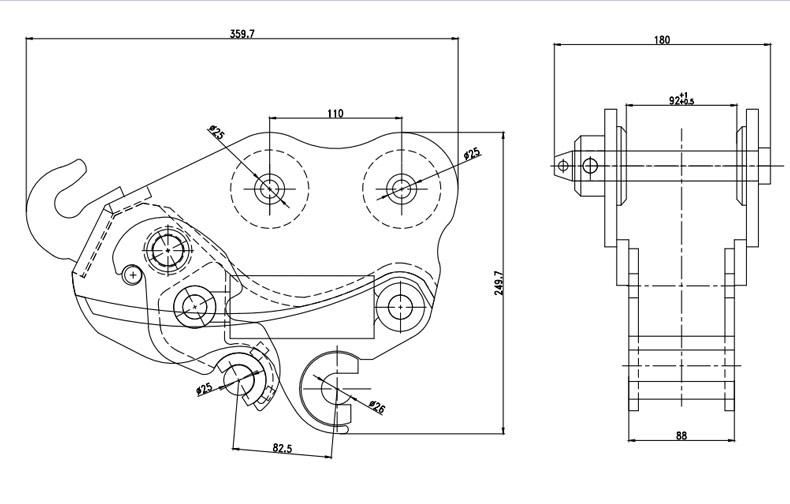

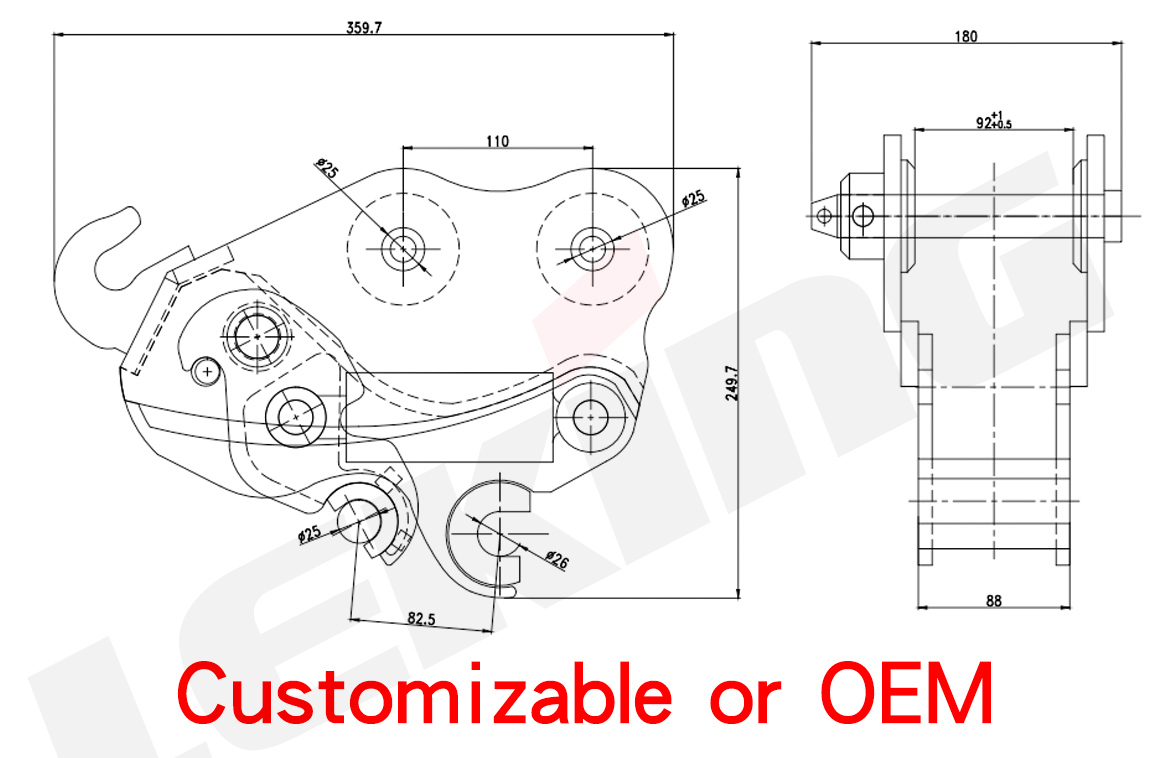

Mechanical Quick Hitch Size Details

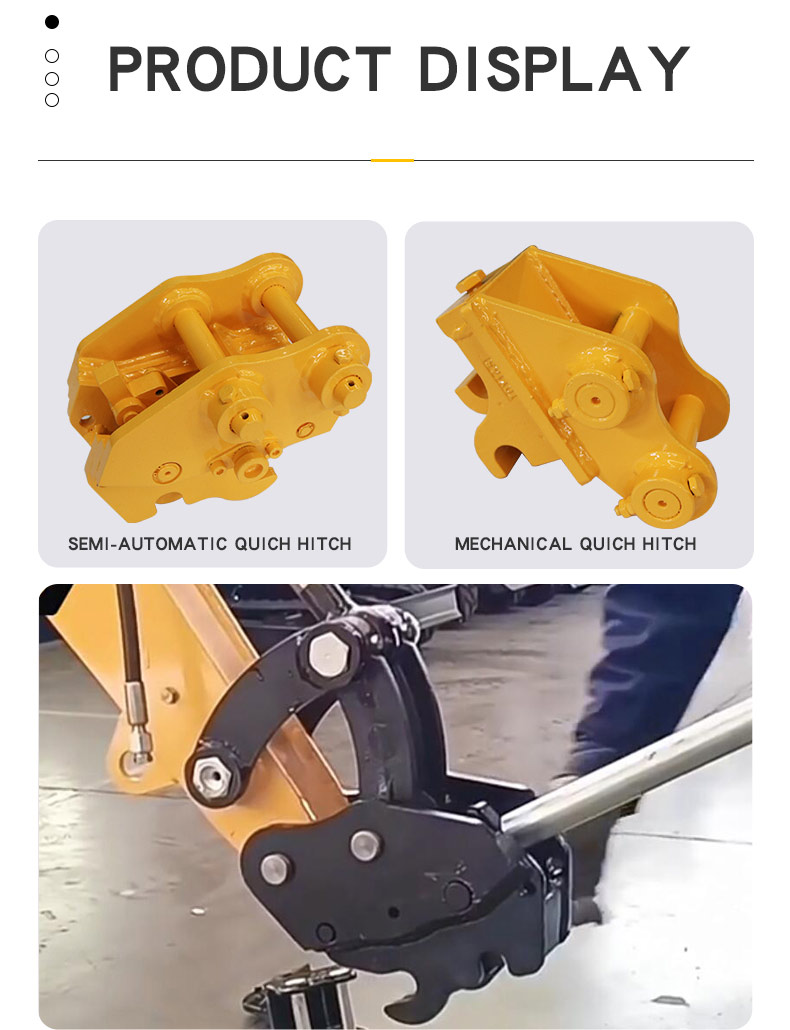

Product classification: According to different working principles, the excavator Quick Hitch can be divided into: hydraulic drive type, mechanical type, butter drive type.

1. Hydraulic drive type: Quick Hitch installs two sets of oil circuits to quick-change joints through the sub-control valve of the oil pump of the excavator itself, and drives the hydraulic cylinder to meet the needs of replacing the working parts of the excavator.

Advantages: large power, high stability, and the simplest operation, just control the electromagnetic switch of the oil circuit;

Disadvantages: increase the routing system and hydraulic cylinder, the cost is relatively high, and the hydraulic pipeline needs to be modified.

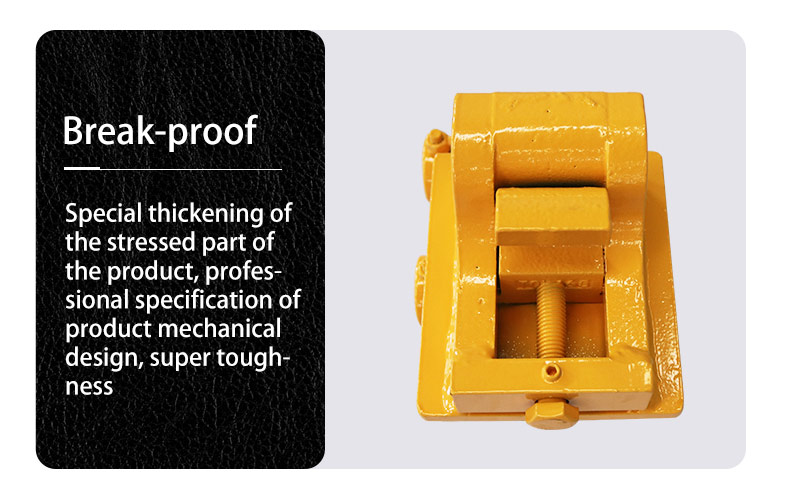

2. Mechanical type: Adjust the distance of the movable block by rotating the mechanical screw, so as to realize the ability to remove and install the working parts of the excavator.

Advantages: simple structure, low cost, no need to modify the pipeline, it can be used by putting on the shaft;

Disadvantages: Due to the long-term high-intensity reciprocating motion of the excavator working parts, it is easy to cause the mechanical screw to loosen and the thread to be damaged. The working environment of the dry excavator is relatively harsh, and it is more laborious to rotate the thread during disassembly and installation.

3. Butter-driven type: The purpose of tensioning the movable block is achieved by injecting butter into the Quick Hitch cylinder.

Advantages: good stability, lower cost than hydraulic type, eliminating the need for oil circuit system and avoiding human error operation.

Disadvantages: When disassembling, you need to let go of the excess butter, which will cause environmental pollution and butter waste, which is more cumbersome than hydraulic replacement; it is better to choose the hydraulic type.